Materials Synthesis

The CMC is equipped with a variety of systems for growing materials for different applications:

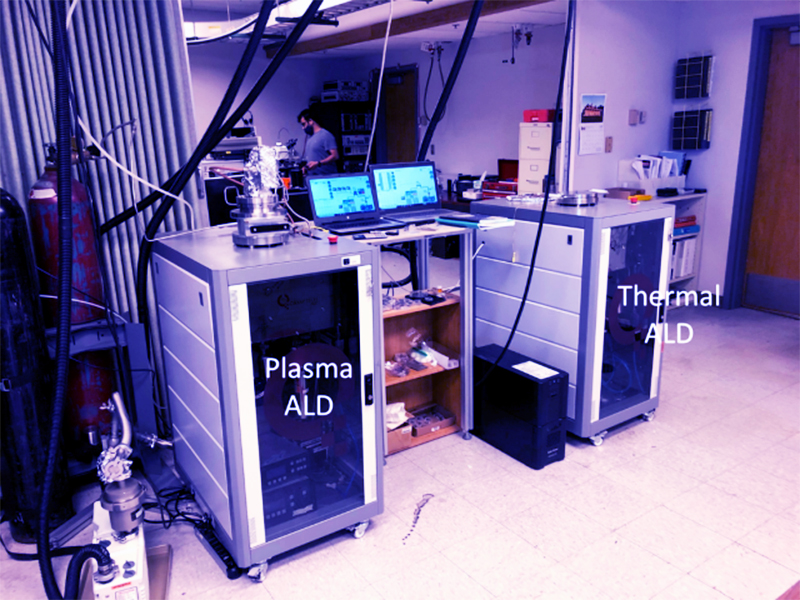

Atomic layer deposition (ALD). Both thermal and plasma ALD systems from OKyay Tech (Turkey) currently with precursors for Al, Ti, Zn, In, and Ga.

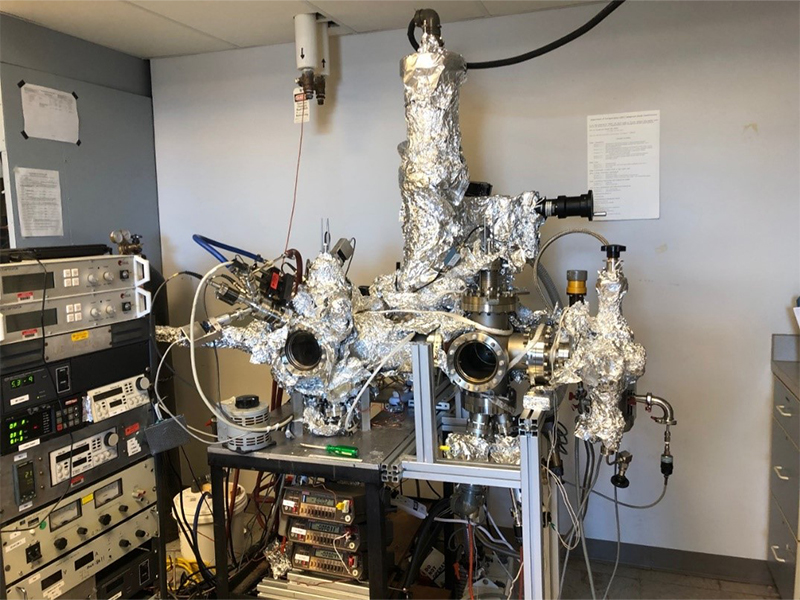

High-Temp Atomic Deposition Layer (HTALD). A custom ALD system capable of depositing thin films at high deposition temperatures than conventional ALD systems. Currently, it is used for GaN thin films deposition.

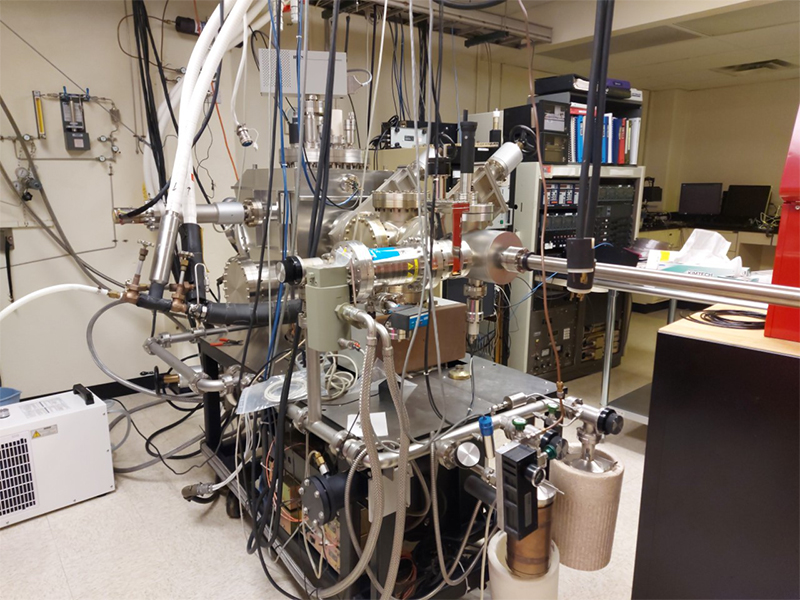

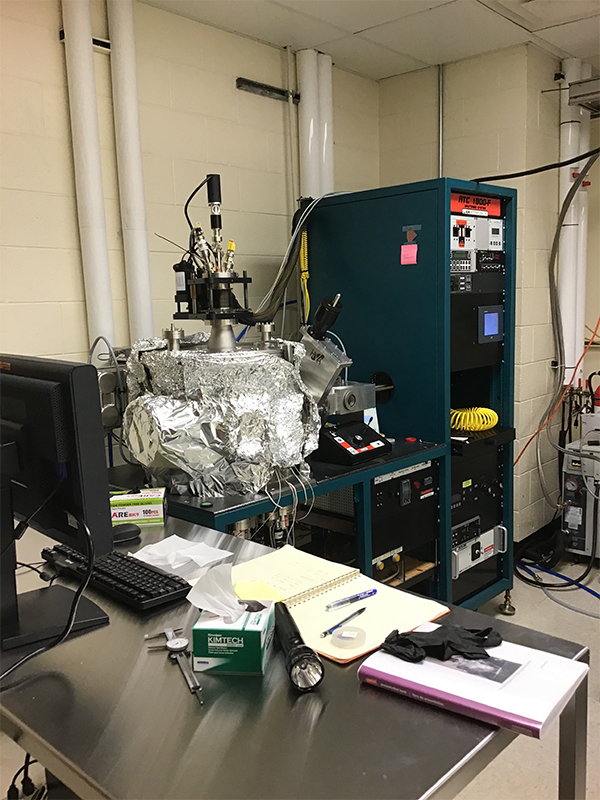

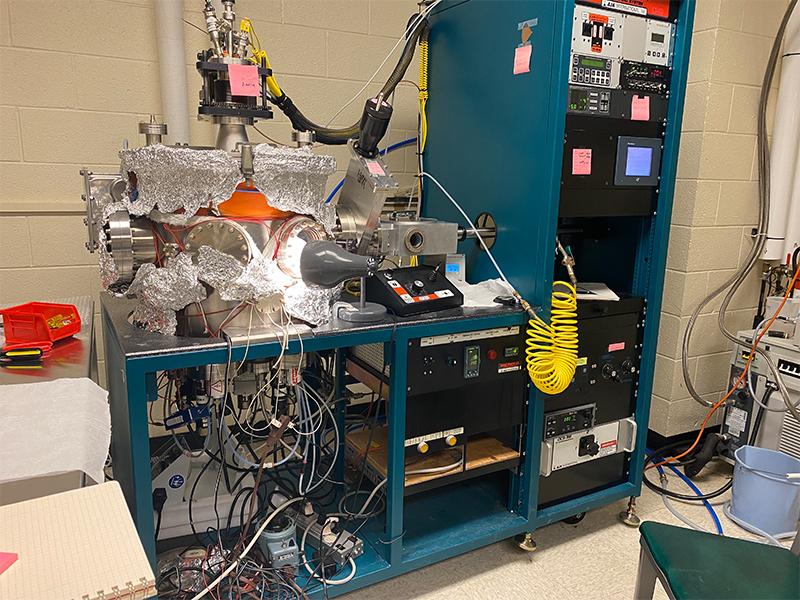

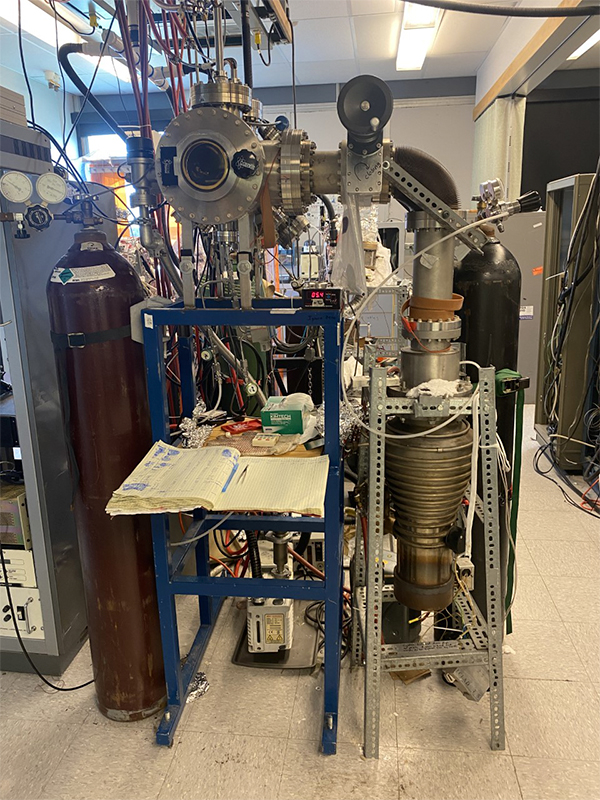

Molecular Beam Epitaxy Deposition (MBE). A customized system that enables MBE growth of different metals like Al, Mg, Ag, Au, and Cu.

Six-gun AJA magnetron sputtering. This ultra-high vacuum system allows depositing high-quality thin films using the following sputtering materials: Al, Cu, Si, Ge, Mn, Fe, Ni, Co, Permalloy, W, Pt, Ir, Ta, MgO, Al2O3, InO.

Magnetron Sputtering System

Vacuum Schlenk Line. It is used for air-sensitive materials synthesis within a fume hood. The systems are equipped with Nitrogen gas, a cold trap, and a vacuum pump. Useful for nanomaterials synthesis and other air sensitive techniques and vacuum sealing of quartz ampules.

Chemical Inkjet printing System. There are 6 inkjet printing stations for chemical printing by design, custom inks can be synthesized and put into the printer ink cartridges, the software can print any design onto any substrate.

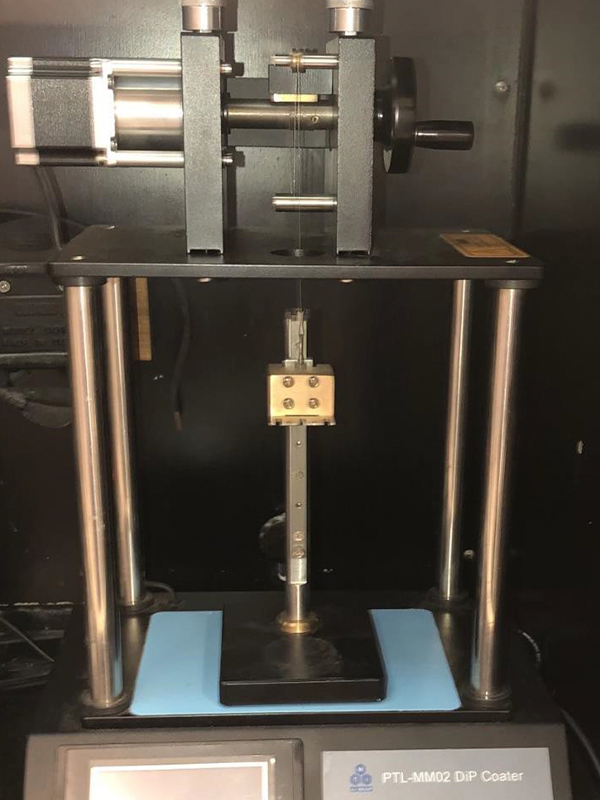

Programmable Dip Coater. This programmable dip coater can control dipping speed, dwell time, dry time, and the number of cycles. Useful for coating, SILAR coating, and other direction reaction techniques. The dip coater has a temperature stage but requires additional permission for use.

Spin-Coater. The VTC-100 vacuum spin coater is equipped with vacuum chucks designed for easy and quick coating for wafers up to 4". The spinning speed is variable from 500-8000 rpm with two programmable segments.

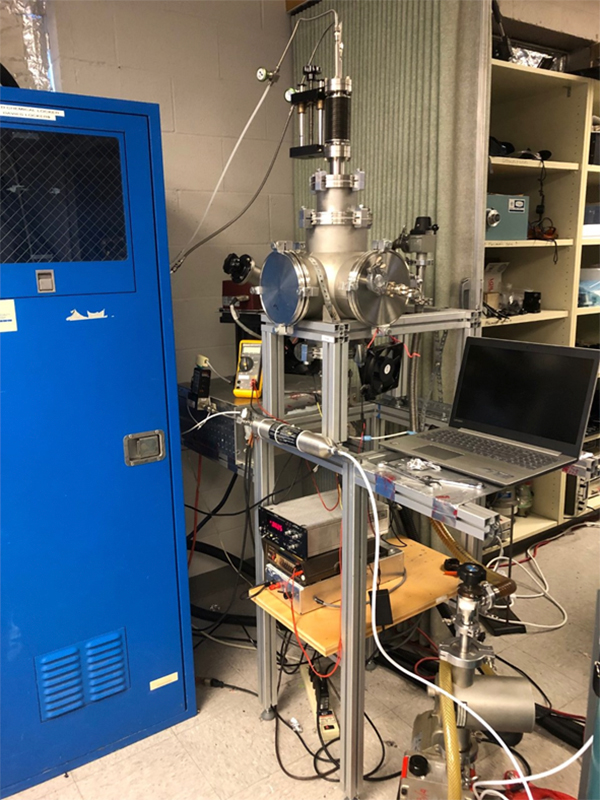

Dual-target sputter deposition. Currently, this sputtering system can deposit either Au or Si without exposing the substrate to air. Targets can be changed as needed. Stages available for substrate rotation.

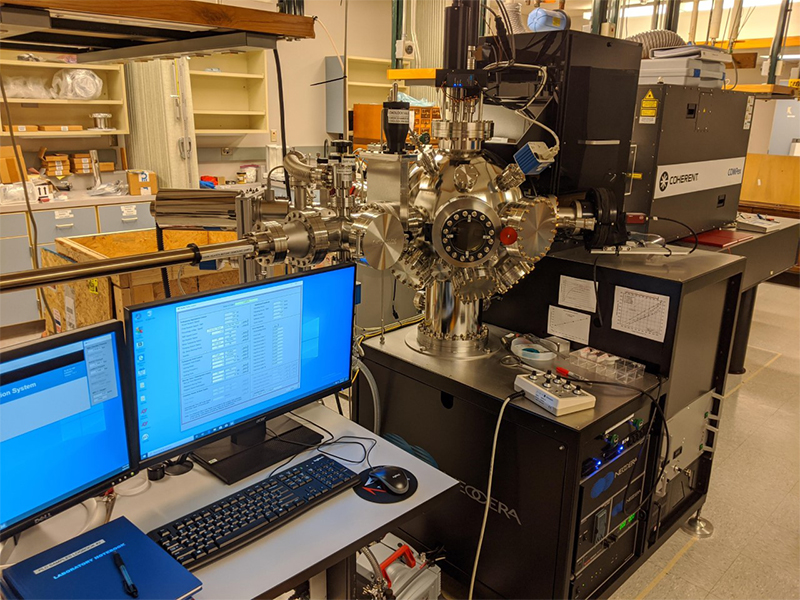

Pulsed Laser Deposition. Neocera Pioneer-180 pulsed laser deposition (PLD) chamber with 6 target carousel, radiative heating stage for temperatures up to 1000 K, mass flow controllers for oxygen, argon, and nitrogen background gases, and Neocera control computer and software.